1. Nazarin tsarin

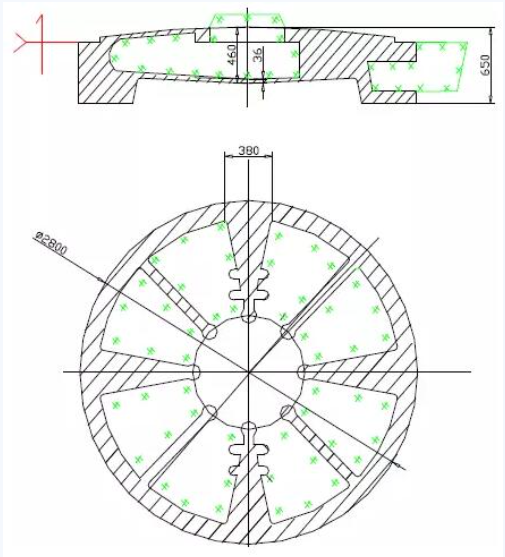

(1) Wannanbawul ɗin malam buɗe idoyana da tsari mai siffar kek mai zagaye, ramin ciki yana da alaƙa kuma yana tallafawa da haƙarƙari guda 8 masu ƙarfafawa, ramin Φ620 na sama yana sadarwa da ramin ciki, da sauran raminbawulAn rufe shi, zuciyar yashi tana da wahalar gyarawa kuma tana da sauƙin lalacewa. Duk shaye-shayen da kuma tsaftace ramin ciki suna kawo manyan matsaloli, kamar yadda aka nuna a Hoto na 1.

Kauri na bangon simintin ya bambanta sosai, matsakaicin kauri na bango ya kai 380mm, kuma mafi ƙarancin kauri na bango shine 36mm kawai. Lokacin da simintin ya taurare, bambancin zafin jiki yana da girma, kuma raguwar da ba ta daidaita ba na iya haifar da ramuka na raguwa da lahani na ramukan raguwa cikin sauƙi, wanda zai haifar da zubewar ruwa a gwajin hydraulic.

2. Tsarin tsari:

(1) An nuna saman rabuwar a Hoto na 1. Sanya ƙarshen da ramuka a kan akwatin sama, yi cikakken tsakiyar yashi a tsakiyar ramin, sannan a tsawaita kan tsakiyar yadda ya kamata don sauƙaƙe ɗaure tsakiyar yashi da motsi na tsakiyar yashi lokacin da aka juya akwatin. Tsayin kan tsakiyar cantilever na ramukan makafi guda biyu a gefe ya fi tsayi fiye da tsawon ramin, don haka tsakiyar nauyi na dukkan tsakiyar yashi yana karkata zuwa gefen kan tsakiyar don tabbatar da cewa tsakiyar yashi yana da ƙarfi kuma yana da ƙarfi.

An yi amfani da tsarin zubar da ruwa mai rufewa, ∑F a ciki: ∑F a kwance: ∑F madaidaiciya = 1:1.5:1.3, sprue ɗin yana amfani da bututun yumbu mai diamita na ciki na Φ120, kuma an sanya guda biyu na tubalan da ba su da ƙarfi 200×100×40mm a ƙasa don hana ƙarfen da ya narke kai tsaye. Don ƙirar yashi mai tasiri, an sanya matattarar yumbu mai kumfa 150×150×40 a ƙasan mai gudu, kuma ana amfani da bututun yumbu 12 masu diamita na ciki na Φ30 don mai gudu na ciki su haɗu daidai da ƙasan mai gudu ta cikin tankin tattara ruwa a ƙasan mai gudu don samar da tsarin zubar da ruwa na ƙasa, kamar yadda aka nuna a Hoto na 2 Essence

(3) Sanya ramukan iska guda 14 ∮20 a cikin saman mold, sanya ramin iska mai girman Φ200 a tsakiyar kan zuciyar, sanya ƙarfe mai sanyi a cikin kauri da manyan sassa don tabbatar da daidaiton ƙarfin simintin, kuma yi amfani da ƙa'idar faɗaɗa graphitization don soke Ana amfani da riser na ciyarwa don inganta yawan amfanin da aka yi. Girman akwatin yashi shine 3600 × 3600 × 1000/600mm, kuma an haɗa shi da farantin ƙarfe mai kauri 25mm don tabbatar da isasshen ƙarfi da tauri, kamar yadda aka nuna a Hoto na 3.

3. Kula da tsari

(1) Tsarin Samfura: Kafin yin samfuri, yi amfani da samfurin Φ50×50mm na yau da kullun don gwada ƙarfin matsi na yashi mai ƙarfi ≥ 3.5MPa, kuma a matse ƙarfe mai sanyi da mai gudu don tabbatar da cewa yashi mai gudu yana da isasshen ƙarfi don daidaita graphite da aka samar lokacin da ƙarfe mai narkewa ya taurare faɗaɗa sinadarai, kuma a hana ƙarfe mai narkewa ya shafi ɓangaren mai gudu na dogon lokaci don haifar da wanke yashi.

Yin tsakiya: An raba tsakiyar yashi zuwa sassa 8 daidai gwargwado ta hanyar haƙarƙari 8 masu ƙarfafawa, waɗanda aka haɗa ta cikin ramin tsakiya. Babu wasu sassan tallafi da shaye-shaye sai kan tsakiyar tsakiya. Idan ba za a iya gyara tsakiyar yashi ba kuma Shaye-shaye, ƙaura da ramukan iska za su bayyana bayan zuba. Saboda faɗin yankin tsakiyar yashi babba ne, an raba shi zuwa sassa takwas. Dole ne ya sami isasshen ƙarfi da tauri don tabbatar da cewa tsakiyar yashi ba zai lalace ba bayan fitar da mold, kuma ba zai lalace ba bayan zuba. Canzawa yana faruwa, don tabbatar da kauri bango iri ɗaya na simintin. Saboda wannan dalili, mun yi ƙashi na musamman na tsakiya, kuma mun ɗaure shi a kan ƙashin tsakiya da igiyar iska don jawo iskar shaye-shaye daga kan tsakiyar don tabbatar da ƙanƙantar mold ɗin yashi lokacin yin tsakiya. Kamar yadda aka nuna a Hoto na 4.

(4) Akwatin rufewa: Ganin cewa yana da wahala a tsaftace yashi a cikin ramin ciki na bawul ɗin malam buɗe ido, an fentin dukkan tsakiyar yashi da layuka biyu na fenti, an goge saman farko da fenti mai launin zirconium mai launin barasa (digiri na Baume 45-55), sannan a fenti saman farko kuma a ƙone. Bayan bushewa, a fenti saman na biyu da fenti mai launin magnesium mai launin barasa (digiri na Baume 35-45) don hana simintin ya manne da yashi da kuma toshewa, wanda ba za a iya tsaftace shi ba. An rataye sashin kan tsakiyar a kan bututun ƙarfe na Φ200 na babban tsarin ƙashin tsakiya da sukurori uku na M25, an gyara shi kuma an kulle shi da akwatin yashi na sama tare da murfi na sukurori kuma an duba ko kauri na bango na kowane ɓangare iri ɗaya ne.

4. Tsarin narkewa da zubawa

(1) Yi amfani da ƙarfe mai inganci na Benxi mai ƙarancin P, S, Ti mai inganci na Q14/16#, sannan a ƙara shi a rabo na 40% ~ 60%; ana sarrafa abubuwan da aka gano kamar P, S, Ti, Cr, Pb, da sauransu sosai a cikin tarkacen ƙarfe, kuma ba a yarda da tsatsa da mai ba, rabon ƙarin shine 25% ~ 40%; dole ne a tsaftace cajin da aka dawo da shi ta hanyar harbin bindiga kafin amfani don tabbatar da tsaftar cajin.

(2) Babban iko na sassan bayan tanderu: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (saura): 0.035% ~0.05%, a ƙarƙashin manufar tabbatar da spheroidization, ya kamata a ɗauki ƙarancin Mg (saura) gwargwadon iko.

(3) Maganin allurar Spheroidization: Ana amfani da magungunan spheroidizers marasa ƙarfi da waɗanda ba a saba gani ba, kuma rabon ƙari shine 1.0% ~ 1.2%. Maganin spheroidization na al'ada ta hanyar wankewa, 0.15% na allurar sau ɗaya ana rufe shi akan nodulizer a ƙasan kunshin, kuma an kammala spheroidization. Sannan ana yin ƙaramin slag don allurar ta biyu ta 0.35%, kuma ana yin allurar ta kwarara ta 0.15% yayin zubarwa.

(5) An yi amfani da tsarin zubar da ruwa cikin sauri a ƙananan zafin jiki, zafin zuba shine 1320°C ~ 1340°C, kuma lokacin zuba shine 70~80s. Ba za a iya katse ƙarfen da aka narke ba yayin zuba, kuma kofin sprue koyaushe yana cike don hana iskar gas da abubuwan da ke cikinsa shiga cikin mold ta hanyar ramin mai gudu.

5. Sakamakon gwajin jefa ƙuri'a

(1) Gwada ƙarfin juriya na tonon simintin: 485MPa, tsayi: 15%, taurin Brinell HB187.

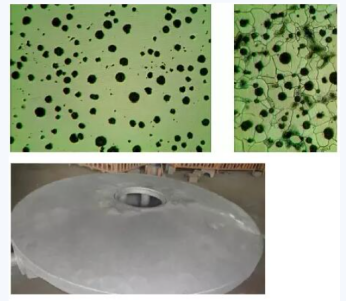

(2) Yawan spheroidization shine kashi 95%, girman graphite shine aji na 6, kuma pearlite shine kashi 35%. An nuna tsarin ƙarfe a Hoto na 5.

(3) Ba a sami wata matsala da za a iya rikodin ta ba a cikin gano lahani na sakandare na UT da MT na muhimman sassa.

(4) Kamanninsa yana da faɗi kuma santsi (duba Hoto na 6), ba tare da lahani na siminti kamar su yashi, tarkacen da aka saka, tarkacen sanyi, da sauransu ba, kauri na bango iri ɗaya ne, kuma girman ya cika buƙatun zane-zanen.

(6) Gwajin matsin lamba na hydraulic 20kg/cm2 bayan sarrafawa bai nuna wani zubewa ba

6. Kammalawa

Dangane da halayen tsarin wannan bawul ɗin malam buɗe ido, matsalar rashin daidaituwa da sauƙin nakasa na babban tsakiyar yashi a tsakiya da kuma wahalar tsaftace yashi ana magance ta ta hanyar jaddada tsarin tsarin, samarwa da gyara tsakiyar yashi da kuma amfani da rufin da aka yi da zirconium. Saita ramukan iska yana hana yiwuwar ramuka a cikin simintin. Daga tsarin sarrafa caji da gudu na tanda, ana amfani da allon matattarar yumbu da fasahar ingate na yumbu don tabbatar da tsarkin ƙarfe mai narkewa. Bayan allurar rigakafi da yawa, tsarin ƙarfe na siminti da kuma cikakken aikin ya kai ga buƙatun abokan ciniki na yau da kullun.

DagaTianjin Tanggu Water-Seal Valve Co., Ltd. Bawul ɗin malam buɗe ido, bawul ɗin ƙofa, Na'urar tace Y, bawul ɗin duba farantin wafer biyuƙera.

Lokacin Saƙo: Afrilu-29-2023