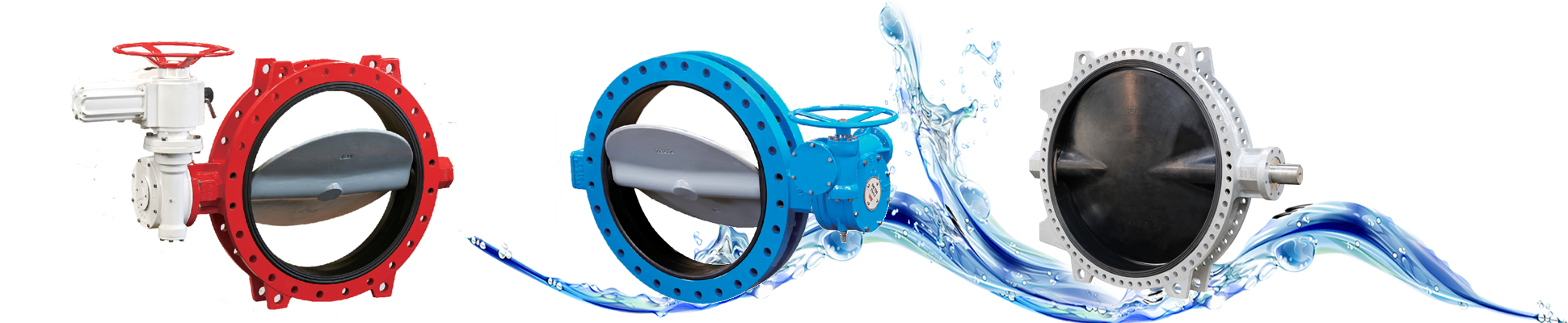

UD Series mai laushi mai malam buɗe ido

Bawul ɗin malam buɗe ido mai laushi na UD Series tsarin Wafer ne mai flanges, fuska da fuska shine jerin EN558-1 20 a matsayin nau'in wafer.

Halaye:

1. Ana yin ramukan gyara akan flange bisa ga daidaitattun daidaito, sauƙin gyara yayin shigarwa.

2. An yi amfani da ƙulli mai fita ko kuma ƙulli mai gefe ɗaya. Sauƙin maye gurbinsa da kulawa.

3. Kujerar hannu mai laushi na iya ware jiki daga kafofin watsa labarai.

Umarnin aiki da samfur

1. Ka'idojin flange na bututu ya kamata su dace da ƙa'idodin bawul ɗin malam buɗe ido; ba da shawarar amfani da flange na wuyan walda, flange na musamman don bawul ɗin malam buɗe ido ko flange na bututun haɗin gwiwa; kada a yi amfani da flange na walda mai zamewa, mai samarwa dole ne ya amince kafin mai amfani ya iya amfani da flange na walda mai zamewa.

2. Ya kamata a duba amfani da yanayin kafin shigarwa ko amfani da bawuloli na malam buɗe ido tare da irin wannan aiki.

3. Kafin shigarwa, mai amfani ya kamata ya tsaftace saman rufin bawul, ya tabbatar babu datti a haɗe; a lokaci guda tsaftace bututun don walda da sauran tarkace.

4. Lokacin shigarwa, dole ne diskin ya kasance a rufe don tabbatar da cewa diskin bai yi karo da flange ɗin bututun ba.

5. Duk ƙarshen wurin zama na bawul suna aiki azaman hatimin flange, ba a buƙatar ƙarin hatimi lokacin shigar da bawul ɗin malam buɗe ido.

6. Ana iya sanya bawul ɗin malam buɗe ido a kowane matsayi (a tsaye, a kwance ko karkata). Bawul ɗin malam buɗe ido mai girman girma na iya buƙatar maƙallin.

7. Haɗuwa yayin jigilar ko adana bawul ɗin malam buɗe ido na iya haifar da rage ƙarfin rufewa. A guji faifan bawul ɗin malam buɗe ido daga haɗuwa zuwa abubuwa masu tauri kuma ya kamata ya kasance a buɗe a matsayi na kusurwa 4 ° zuwa 5 ° domin kiyaye saman rufewa daga lalacewa a wannan lokacin.

8. Tabbatar da daidaiton walda mai lanƙwasa kafin shigarwa, walda bayan shigar da bawul ɗin malam buɗe ido na iya haifar da lalacewa ga robar da murfin kiyayewa.

9. Lokacin amfani da bawul ɗin malam buɗe ido wanda iska ke aiki da shi, ya kamata tushen iskar ya kasance mai tsabta da bushewa don hana wasu sassan iska shiga cikin mai aiki da iskar numfashi da kuma shafar aikin aiki.

10. Ba tare da buƙatu na musamman da aka lura a cikin siyan bawul ɗin malam buɗe ido ba, za a iya ɗora shi a tsaye kawai kuma don amfani na ciki kawai.

11. Ya kamata a gano dalilan da suka sa aka samu matsala, a warware matsalar, kada a buga, a buga, a ba wa mai sarrafa lever ƙarin ƙarfi don ya buɗe ko rufe bawul ɗin malam buɗe ido da ƙarfi.

12. A lokacin ajiya da lokacin da ba a yi amfani da shi ba, ya kamata a bar bawul ɗin malam buɗe ido a bushe, a ɓoye su a cikin inuwa kuma a guji abubuwa masu cutarwa da ke kewaye da su daga zaizayar ƙasa.

Girma:

| DN | A | B | H | D0 | C | D | K | d | N-do | 4-M | b | D1 | D2 | N-d1 | F | Φ2 | W | J | H1 | H2 | ||||

| 10 | 16 | 10 | 16 | 10 | 16 | 10 | 16 | |||||||||||||||||

| 400 | 400 | 325 | 51 | 390 | 102 | 580 | 515 | 525 | 460 | 12-28 | 12-31 | 4-M24 | 4-M27 | 24.5 | 175 | 140 | 4-18 | 22 | 33.15 | 10 | 36.15 | 337 | 600 | |

| 450 | 422 | 345 | 51 | 441 | 114 | 640 | 565 | 585 | 496 | 16-28 | 16-31 | 4-M24 | 4-M27 | 25.5 | 175 | 140 | 4-18 | 22 | 37.95 | 10 | 40.95 | 370 | 660 | |

| 500 | 480 | 378 | 57 | 492 | 127 | 715 | 620 | 650 | 560 | 16-28 | 16-34 | 4-M24 | 4-M30 | 26.5 | 175 | 140 | 4-18 | 22 | 41.12 | 10 | 44.12 | 412 | 735 | |

| 600 | 562 | 475 | 70 | 593 | 154 | 840 | 725 | 770 | 658 | 16-31 | 16-37 | 4-M27 | 4-M33 | 30 | 210 | 165 | 4-22 | 22 | 50.63 | 16 | 54.65 | 483 | 860 | |

| 700 | 624 | 543 | 66 | 695 | 165 | 910 | 840 | 840 | 773 | 20-31 | 20-37 | 4-M27 | 4-M33 | 32.5 | 300 | 254 | 8-18 | 30 | 63.35 | 18 | 71.4 | 520 | 926 | |

| 800 | 672 | 606 | 66 | 795 | 190 | 1025 | 950 | 950 | 872 | 20-34 | 20-41 | 4-M30 | 4-M36 | 35 | 300 | 254 | 8-18 | 30 | 63.35 | 18 | 71.4 | 586 | 1045 | |

| 900 | 720 | 670 | 110 | 865 | 200 | 1125 | 1050 | 1050 | 987 | 24-34 | 24-41 | 4-M30 | 4-M36 | 37.5 | 300 | 254 | 8-18 | 34 | 75 | 20 | 84 | 648 | 1155 | |

| 1000 | 800 | 735 | 135 | 965 | 216 | 1255 | 1160 | 1170 | 1073 | 24-37 | 24-44 | 4-M33 | 4-M39 | 40 | 300 | 254 | 8-18 | 34 | 85 | 22 | 95 | 717 | 1285 | |

| 1100 | 870 | 806 | 150 | 1065 | 251 | 1355 | 1270 | 1270 | 1203 | 28-37 | 28-44 | 4-M33 | 4-M39 | 42.5 | 350 | 298 | 8-22 | 34 | 95 | ## | 105 | 778 | 1385 | |

| 1200 | 940 | 878 | 150 | 1160 | 254 | 1485 | 1380 | 1390 | 1302 | 28-41 | 28-50 | 4-M36 | 4-M45 | 45 | 350 | 298 | 8-22 | 34 | 105 | 28 | 117 | 849 | 1515 | |

| 1400 | 1017 | 993 | 150 | 1359 | 279 | 1685 | 1590 | 1590 | 1495 | 28-44 | 28-50 | 8-M39 | 8-M45 | 46 | 415 | 356 | 8-33 | 40 | 120 | 32 | 134 | 963 | 1715 | |

| 1500 | 1080 | 1040 | 180 | 1457 | 318 | 1280 | 1700 | 1710 | 1638 | 28-44 | 28-57 | 8-M39 | 8-M52 | 47.5 | 415 | 356 | 8-33 | 40 | 140 | 36 | 156 | 1039 | 1850 | |

| 1600 | 1150 | 1132 | 180 | 1556 | 318 | 1930 | 1820 | 1820 | 1696 | 32-50 | 32-57 | 8-M45 | 8-M52 | 49 | 415 | 356 | 8-33 | 50 | 140 | 36 | 156 | 1101 | 1960 | |

| 1800 | 1280 | 1270 | 230 | 1775 | 356 | 2130 | 2020 | 2020 | 1893 | 36-50 | 36-57 | 8-M45 | 8-M52 | 52 | 475 | 406 | 8-40 | 55 | 160 | 40 | 178 | 1213 | 2160 | |

| 2000 | 1390 | 1350 | 280 | 1955 | 406 | 2345 | 2230 | 2230 | 2105 | 40-50 | 40-62 | 8-M45 | 8-M56 | 55 | 475 | 406 | 8-40 | 55 | 160 | 40 | 178 | 1334 | 2375 |