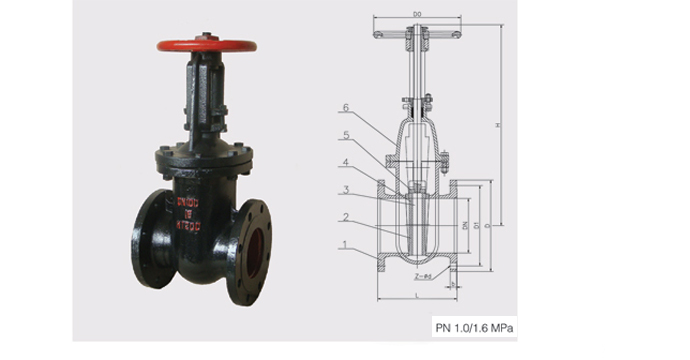

WZ Series Metal zaune OS&Y ƙofar bawul

Bayani:

Bawul ɗin ƙofar WZ Series na ƙarfe da ke zaune a OS&Y yana amfani da ƙofar ƙarfe mai laushi wanda ke ɗauke da zoben tagulla don tabbatar da cewa babu ruwa a rufewa. Ana amfani da bawul ɗin ƙofar OS&Y (Screw da Yoke) galibi a cikin tsarin feshin kariya daga gobara. Babban bambanci daga bawul ɗin ƙofar NRS (Non Rising Stem) na yau da kullun shine cewa an sanya bawul ɗin tushe da goro a wajen jikin bawul ɗin. Wannan yana sauƙaƙa ganin ko bawul ɗin a buɗe yake ko a rufe yake, domin kusan dukkan tsawon bawul ɗin yana bayyane lokacin da bawul ɗin yake buɗe, yayin da bawul ɗin baya bayyana lokacin da bawul ɗin yake rufe. Gabaɗaya wannan buƙata ce a cikin waɗannan nau'ikan tsarin don tabbatar da saurin sarrafa yanayin tsarin.

Jerin kayan aiki:

| Sassan | Kayan Aiki |

| Jiki | Iron ɗin ƙarfe, ƙarfe mai ƙarfi |

| Faifan diski | Iron ɗin ƙarfe, ƙarfe mai ƙarfi |

| Tushe | SS416, SS420, SS431 |

| Zoben kujera | Tagulla/Tagulla |

| Bonnet | Iron ɗin ƙarfe, ƙarfe mai ƙarfi |

| Gyadar tushe | Tagulla/Tagulla |

Fasali:

Goro mai kauri: An yi goron da aka yi da ƙarfe mai kauri wanda ke da ƙarfin shafawa wanda ke ba da damar yin aiki yadda ya kamata tare da bakin ƙarfe.

Madauri: An yi madauri daga ƙarfe mai kauri tare da zoben fuska na jan ƙarfe waɗanda aka ƙera su zuwa kyakkyawan saman don tabbatar da cewa an rufe su da zoben wurin zama na jiki. An yi amfani da zoben fuskar madauri daidai kuma an ɗaure su da madauri. Jagororin da ke cikin madauri suna tabbatar da rufewa iri ɗaya ba tare da la'akari da matsin lamba mai yawa ba. Madauri yana da babban madauri mai zurfi don tushe wanda ke tabbatar da cewa ruwa ko ƙazanta ba za su iya taruwa ba. Madauri yana da cikakken kariya ta hanyar shafa epoxy mai haɗin gwiwa.

Gwajin matsin lamba:

| Matsi na musamman | PN10 | PN16 | |

| Matsin gwaji | Ƙulle | 1.5 Mpa | 2.4 Mpa |

| Hatimcewa | 1.1 Mpa | 1.76 Mpa | |

Girma:

| Nau'i | DN(mm) | L | D | D1 | b | Z-Φd | H | D0 | Nauyi (kg) |

| RS | 40 | 165 | 150 | 110 | 18 | 4-Φ19 | 252 | 135 | 11/12 |

| 50 | 178 | 165 | 125 | 20 | 4-Φ19 | 295 | 180 | 17/18 | |

| 65 | 190 | 185 | 145 | 20 | 4-Φ19 | 330 | 180 | 21/22 | |

| 80 | 203 | 200 | 160 | 22 | 8-Φ19 | 382 | 200 | 27/28 | |

| 100 | 229 | 220 | 180 | 24 | 8-Φ19 | 437 | 200 | 35/37 | |

| 125 | 254 | 250 | 210 | 26 | 8-Φ19 | 508 | 240 | 46/49 | |

| 150 | 267 | 285 | 240 | 26 | 8-Φ23 | 580 | 240 | 66/70 | |

| 200 | 292 | 340 | 295 | 26/30 | 8-Φ23/12-Φ23 | 760 | 320 | 103/108 | |

| 250 | 330 | 395/405 | 350/355 | 28/32 | 12-Φ23/12-Φ28 | 875 | 320 | 166/190 | |

| 300 | 356 | 445/460 | 400/410 | 28/32 | 12-Φ23/12-Φ28 | 1040 | 400 | 238/274 | |

| 350 | 381 | 505/520 | 460/470 | 30/36 | 16-Φ23/16-Φ28 | 1195 | 400 | 310/356 | |

| 400 | 406 | 565/580 | 515/525 | 32/38 | 16-Φ28/16-Φ31 | 1367 | 500 | 440/506 | |

| 450 | 432 | 615/640 | 565/585 | 32/40 | 20-Φ28/20-Φ31 | 1460 | 500 | 660/759 | |

| 500 | 457 | 670/715 | 620/650 | 34/42 | 20-Φ28/20-Φ34 | 1710 | 500 | 810/932 | |

| 600 | 508 | 780/840 | 725/770 | 36/48 | 20-Φ31/20-Φ37 | 2129 | 500 | 1100/1256 |